Whether a cylinder is top class or mass-produced, cannot necessarily be seen – but it is soon noticed in running operations. What makes us stand out from the general market is the intelligent force that works from inside out. Because we fully harmonise product, design and manufacturing intelligence, we offer innovative customer-specific cylinder engineering in uncompromising quality. Why put up with less?

Product Intelligence

BÜTER Group has hundreds of patents and utility models currently in process or that have been applied for. This makes BÜTER Group an uncontested engineering pioneer in the cylinder market. Yet more important: These protected inventions result in a wide range of benefits to the customer. For example, hydraulic dampers: Short lines and rapid braking make for clear design, time and energy advantages. An innovation that is only available from BÜTER today – and that will make its mark on the market of tomorrow. This certainly applies to our threaded and laser cylinders, which are replacing the conventionally welded cylinders with an increasing number of customers.

A new tractor model that specifies a different installation dimension for the cylinder? A waste disposal vehicle that needs an extremely compact hydraulic damper? Whenever customers come to us with their specific requirements, the BÜTER Group approach is: There's no such thing as "can't be done". The engineering team takes over and draws up the blueprint for the first sample cylinder on the basis of the customer's wishes in a matter of weeks. In doing so, the team is able to rely on experience from thousands of products and make use of modular elements, saving time and money. From test run up to serial production will then not take long.

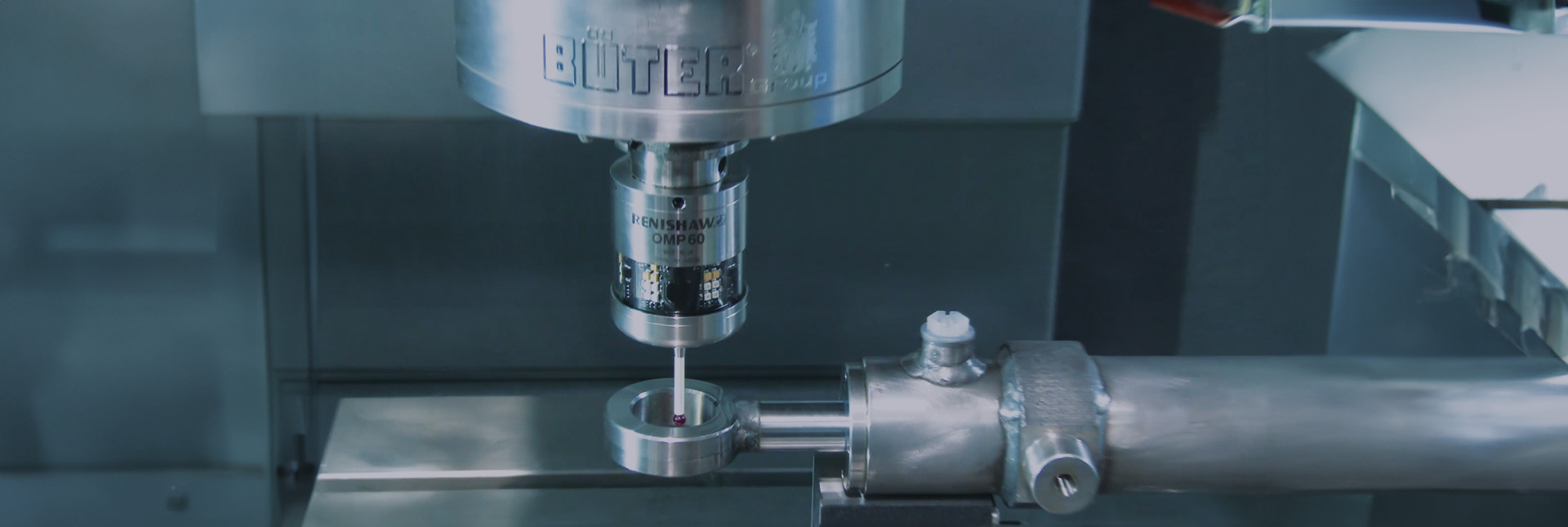

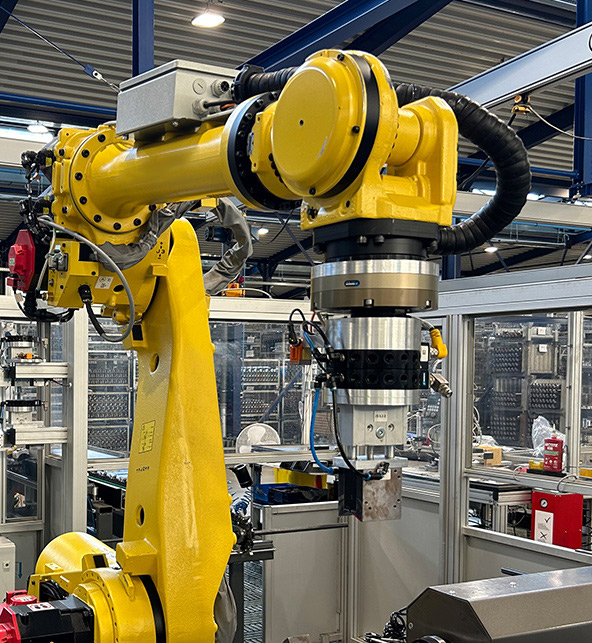

Intelligent cylinders demand suitable manufacturing technologies. The BÜTER Group machine park for this reason is largely derived from its own mechanical engineering work. This development work in fully automated loading equipment and other automated systems works to the customer's benefit: Apart from traditional welding processes with the highest quality, BÜTER Group can provide economical serial production of threaded and laser cylinders. A tailor-made production planning and manufacturing system makes for systematic procedures.

Cylinders are required to function faultlessly, sometimes under extreme conditions, and for just as long as the machinery in which they have been installed. And for that reason, the BÜTER Group stresses top quality without any reservations. Complaints low, customer satisfaction high: We make good on this claim year after year. Endurance tests in our own laboratories, QA trial stages in all steps of production, seamless inspection of automated threaded versions, and spectrum analyses or salt spray tests in accordance with DIN EN ISO 9227 are merely examples of our comprehensive quality management. Certification in accordance with ISO 9001:2015 is a matter of course.