The BÜTER Group manufactures all common types of cylinders for mobile and stationary applications and does so in impressive quality thanks to proprietary, in-house developed processes. They function so reliably throughout their entire service life that you don't even notice them.

Completely in a league of its own

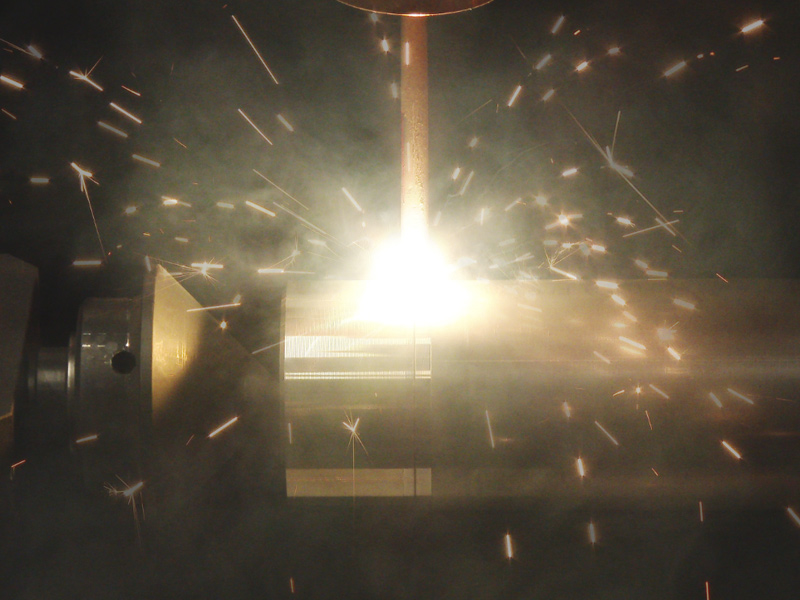

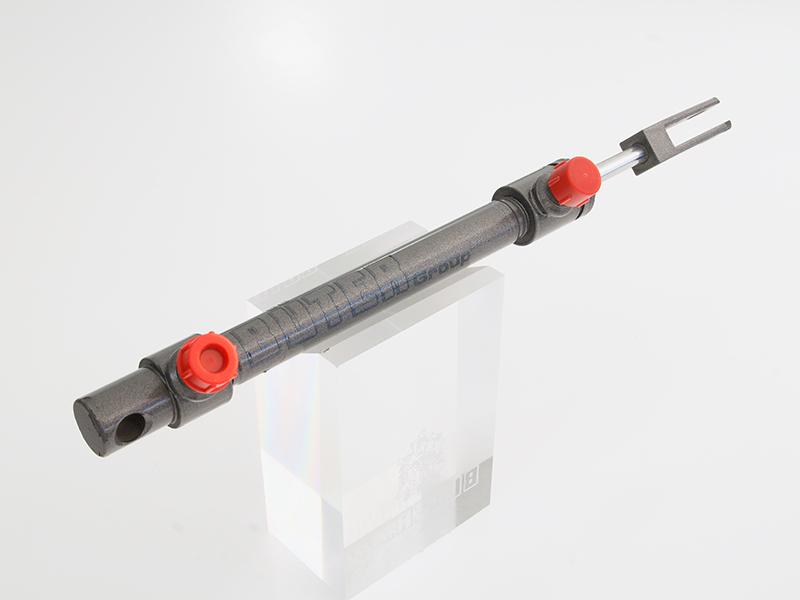

The laser welded Smart Cylinder is set to change the rules of the game in the cylinder market. The laser's power, concentrated on less than one millimetre, enables welding without welding wire and supreme tightness without seals. All of this is achieved with a considerably reduced tube wall thickness. And available nowhere else on the market. This revolutionary process yields tangible advantages to the customer: longer service lives, weight-saving and reduced operating costs and changing seals or guide elements is no longer required. The in-house manufacturing process is also revolutionary: It enables series production of the designed Smart Cylinder. Entirely according to the customer's requirements and regardless of cylinder type.

Smart contribution to protecting the climate

The Smart Cylinder is a green cylinder as well. Because considerably less steel has to be used. Because welding wire and basic materials can be saved. Because the energy demand per cylinder drops. And of course because premature wear and leaks are now finally a thing of the past. .

Precision taken to the extreme

No distortion, no weld seam, no thick-walled tube: Compared to a MAG-welded hydraulic cylinder, the screw-in cylinder invented by Josef Büter offers clear advantages. The critical point, unintentional loosening of the screw connection, was solved by a patented screw design and position lock. Manufacturing accuracy is what counts. High-precision measuring tools, developed in-house, of course are the basis for specific pipe processing machines that ensure precise installation and stroke lengths.

Autonomous thanks to integrated sensors

The screwdriving cylinder unfolds its full potential with an integrated sensor system that monitors and controls the position, path and speed in a well-protected interior. This means that the cylinder can be integrated into the customer's automated control system, whether for satellite-controlled combine harvesters, automated conveyor technology or next-generation construction machinery fleets.

Strong forces in an especially compact design can be achieved with Microcylinders – in the usual sizes or as a special product tailormade to the customer's precise wishes and requirements. They are designed for applications in which short installation dimensions and limited weight are required, for example in high-tech applications.

Details

Plunger cylinders reduce hydraulic cylinder complexity through the fact that the cylinder's piston rod also serves as a piston. This raises the cylinder's mechanical efficiency, and they can be produced more cost effective. Plunger cylinders are exclusively single-acting and are installed in lifting technology or in hybrid systems, among other areas.

Details

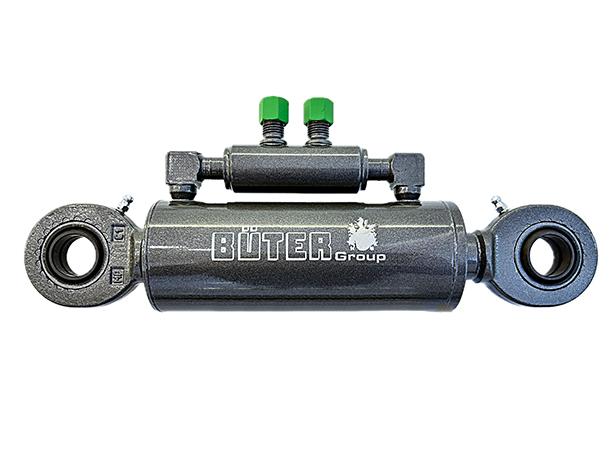

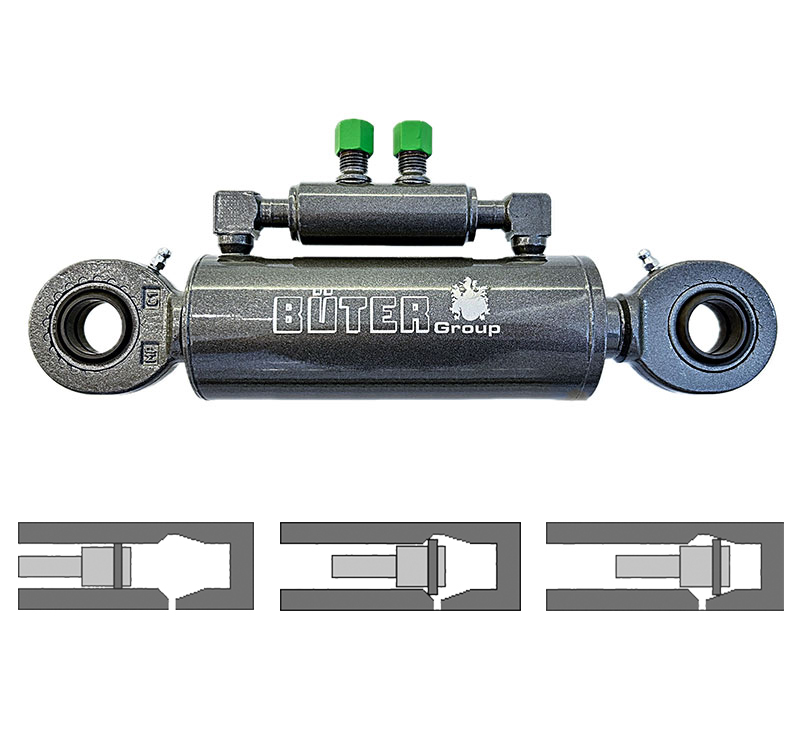

A double-acting hydraulic cylinder can move in and out with its two piston surfaces, where the pulling force on moving in is smaller on account of the smaller surface than the pressure on moving out. It is needed for mobile applications in particular.

Details

Accumulator cylinders combine the roles of hydraulic cylinders and hydraulic accumulators. This simplifies assembly and reduces the risk of leaks. As the piston rod moves out, pressure is applied to the hydraulic cylinder through a connecting hose on the piston side, and the accumulator on the piston ring side is gradually filled with mineral oil.

Details

Hydraulic cylinders with position measuring system controls the cylinder's position, path and speed. The sensitive sensor technology is protected inside the cylinder, so that the system can be used even under extremely difficult working conditions – special protection measures are not required.

Details

When large masses or weights need to be moved at high speeds, cylinders and adjacent components are subject to high loads. Hydraulic cylinders with end-position cushioning protect systems, machines and vehicles from damage caused by overloading. They also significantly and sustainably reduce noise levels. This applies all the more when higher speeds are reached during movement, as is the case with vehicles for waste collection, for example.

Details

Pull cylinders are used to generate a pulling force. They are able to move heavy loads safely and precisely. For this reason, they are essential for a wide range of applications in industry and the manufacturing sector in particular.

Details

Hydraulic cylinders with valves protect people and machinery. We secure braking of the cylinder movement by means of integrated valve technology, preventing unwanted lowering, even when the hose connection fails – reliable at all times. From recycling and demolition to agricultural machinery, construction machinery and lifting devices – tailormade to the requirements.

Details

Steering cylinders form the core of hydraulic steering of heavy machinery, such as tractors, wheeled excavators diggers and all-terrain forklifts. Whether it is on the front or rear axle, or with hydraulic four-wheel steering – steering cylinders can be controlled extremely precise, retaining the steering angle with great power and reliability.

Details

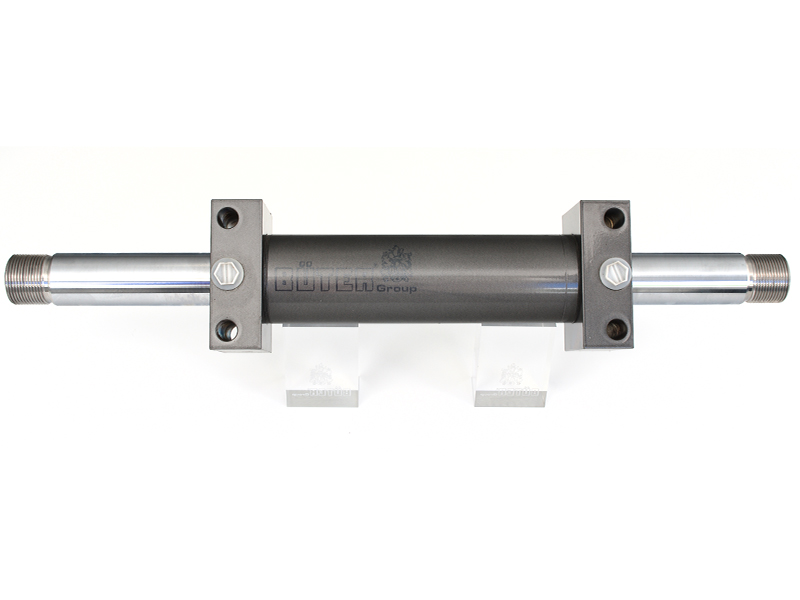

Double-ended synchronized cylinders (also called synchronised cylinders) are special hydraulic cylinders in which the piston rod is able to travel out on both sides. They can be used flexible for pull or push and are used mainly for moving components at constant speed, such as for example for controlling a rudder, a valve or a steering shaft.

Details