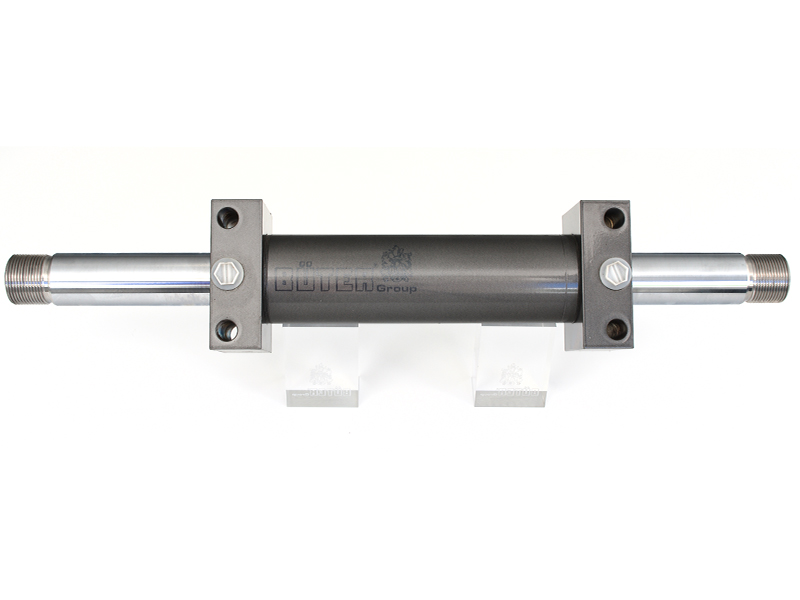

Double-Ended Synchronized Cylinder

Properties according to model

Double-ended synchronized cylinders (also called synchronised cylinders) are special hydraulic cylinders in which the piston rod is able to travel out on both sides. They can be used flexible for pull or pressure and are used mainly for moving components at constant speed, such as for example for controlling a rudder, a valve or a steering shaft.

BÜTER Group double-ended synchronized cylinders stand out with the following advantages:

- Easy running resulting from high-quality manufacture

- Constantly high level of quality

- Simple assembly and disassembly

- Low manufacturing costs through modular design

As the customer, you are able to choose between a range of dimensions, attachment methods (for example pivot bearing, tension bush, bore) and special models.

Contact

Phone: +49 (0)5934 708-0

Email: mail@bueter.com

- Nominal pressure: 210 bar (Higher pressures possible on request)

- Hydraulic fluid: Mineral oil

- Temperature range for sealing and guide elements: -20 to +80 °C

- Lifting speed: < 0.5 m/s

- Piston rod coating: e.g. C45E, hard chrome plated